Easy Way to Find Vacuum Leak in My Ford Van

Dan Ferrell writes about DIY car maintenance and repair. He has certifications in Automation and Control Technology and Technical Writing.

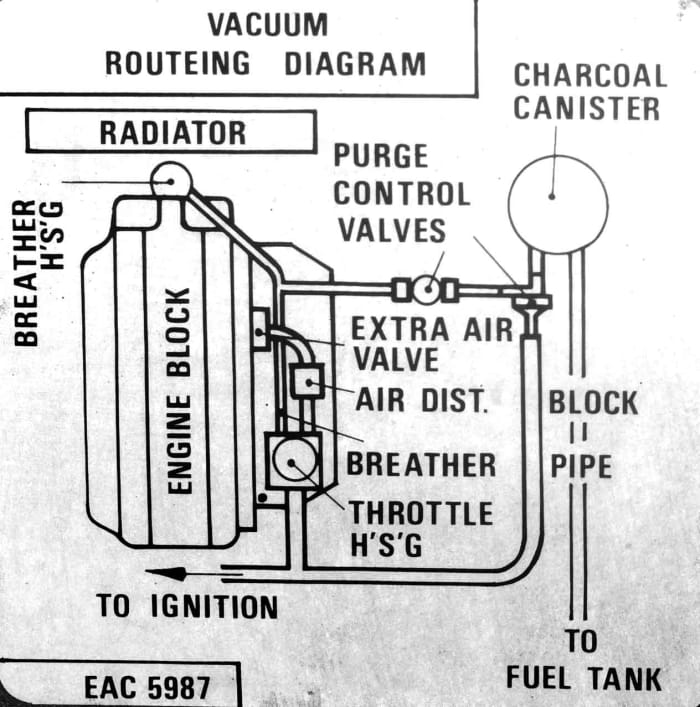

A decal showing a vehicle vacuum hose routing.

Photo courtesy of James A O on Flickr.

Find and Fix a Vacuum Leak

A vacuum leak can cause a myriad of drivability problems, as it introduces extra, unwanted air into the engine, leaning out the air/fuel mixture. Modern internal combustion (multi-port fuel injection) engines use intake vacuum to operate sensors, actuators, and power brakes (on some vehicles). Older engines also use it to operate some emission control devices and to pull fuel into the combustion chamber.

So even a small vacuum leak can trick you, and your car computer, into believing a particular sensor or system needs fixing. Then you start replacing components hoping you'll fix the problem, unsuccessfully.

Often, a vacuum leak makes an audible hissing sound, which makes it easy to find; other times, though, you won't hear anything. Car shops use special, costly equipment to detect hard-to-find leaks. But before you head to the shop, you can apply simple techniques used to track most common vacuum leaks.

This guide not only helps you find a vacuum leak or an obstructed vacuum hose and gives you useful repair tips, but it also tells you what engine performance problems may point to a potential vacuum leak. So let's start there.

| Index |

|---|

| I. When Should I Troubleshoot for a Potential Vacuum Leak? |

| Vacuum Leak Symptoms |

| Vacuum Leak Related Trouble Codes |

| II. How to Find a Vacuum Leak |

| Using a Vacuum Gauge |

| III. Checking the Intake Manifold for Vacuum Leaks |

| IV. Using a Hand Vacuum Pump to Test Devices for Vacuum Leaks |

| V. Vacuum Hose Repair Tips |

Throttle body and intake manifld gaskets can develop leaks as well.

Photo courtesy of James A O on Flickr.

I. When Should I Troubleshoot for a Potential Vacuum Leak?

Vacuum hoses are a common source of engine performance problems. After miles of service, vacuum hoses wear out, harden, split or soften; and vacuum tubing deteriorates, turns brittle, and breaks, causing all kinds of engine performance problems.

So whenever you notice an engine performance problem and can't seem to find the source, include a vacuum leak diagnostic into your repair strategy.

Depending on your particular vehicle make and model, you may find various sensors and actuators that depend on a good vacuum source to operate. For example, some engines use a Manifold Absolute Pressure (MAP) sensor that requires vacuum to measure outside air pressure.

A MAP sensor vacuum leak can upset ignition timing and engine stability and efficiency. A vacuum leak can also prevent an EGR valve from opening, cause engine overheating, and increase harmful emissions. This type of leak can also affect the Positive Crankcase Ventilation (PCV) system.

Vacuum Leak Symptoms

Here is a list of performance problems to keep in mind, as they might possibly be related to a vacuum leak:

- Backfiring

- Hesitation

- Hard starting

- Low engine power

- Misfiring (usually random. You may get trouble code P0300)

- Poor fuel economy

- Poor acceleration

- Rough idle

- High idle or very low idle, depending on vehicle model.

- Stalling

- Stumbling

- Check Engine Light on

- Oxygen sensor reports a lean mixture continuously.

- Poor brake performance (on vacuum-type power brakes)

Keep in mind that these symptoms are not exclusive to a vacuum leak. For example, a bad EGR valve, bad compression, or ignition timing problems may cause one or more of these symptoms as well.

The following diagnostic trouble codes (DTCs) may be triggered by different types of faults, including a vacuum leak.

Scroll to Continue

Read More from AxleAddict

| Trouble Code | Description |

|---|---|

| P0505 | Idle control system malfunction |

| P0301-8 | Cylinder specific misfire |

| P0170 | Fuel trim malfunction (bank 1) |

| P0171 | System too lean (bank 1) |

| P0173 | Fuel trim malfunction (bank 2) |

| P0174 | System too lean (bank 2) |

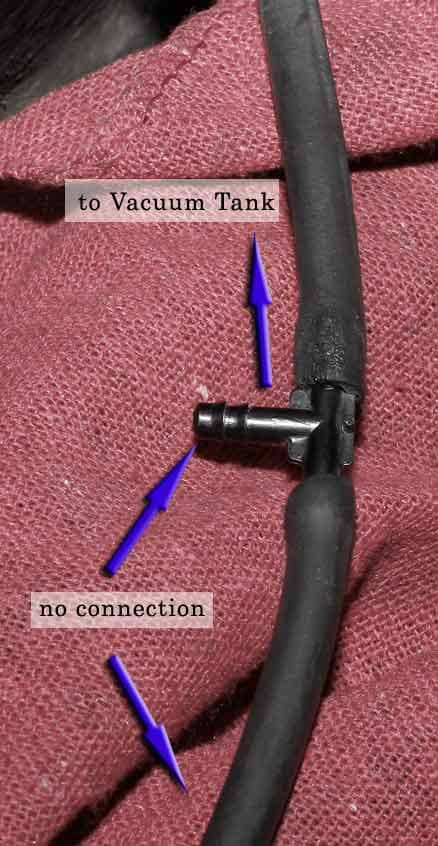

Check vacuum hose connectors for cracks that may leak vacuum.

Photo courtesy of James A O on Flickr.

II. How to Find a Vacuum Leak

OK. You have an engine performance problem and you want to do some vacuum leak checking, where do you start?

First, locate the vacuum diagram for your vehicle. You may find a copy of the vacuum diagram on your car owner's manual, but most car manufacturers include a diagram inside the engine compartment. Raise the hood and look around the front of the engine compartment for a decal.

If you can't find one on your manual or in the engine compartment, you can buy one at your dealer service department. Another source is your vehicle repair manual. You can buy an inexpensive aftermarket vehicle repair manual at your local auto parts store or online. The repair manual has all kinds of useful information you can use for maintaining and troubleshooting many car systems. So you'll make a good investment.

The vacuum diagram shows the different vacuum-controlled devices and how they interconnect. Newer vehicle models depict the components' resemblance and their location.

OK. Now that you have the vacuum diagram for your vehicle, you can start troubleshooting for a potential vacuum leak. However, even if you don't have the diagram right now, you still can follow the next steps.

(Note: If you are trying to find a potential vacuum leak because of a trouble code you retrieved after your Check Engine Light came on, your car computer may be adjusting the air/fuel ratio to compensate; so the engine might not sound as if it had a performance problem. If so, unplug the throttle position sensor [mounted on the throttle body] or oxygen sensor, to force the computer to run the engine in "hard code" mode [open loop], so you can hear the engine rough idle. This will make it easier to detect the vacuum leak source during your diagnostic.)

If you suspect a particular device (or several), you can start with that device. Otherwise, follow the diagram and start checking each hose. If you don't have the diagram, check each vacuum hose as you go around the engine. Most vacuum hoses are thin and soft, except for the one used on the brake booster, which is thicker and more sturdy in design, and possibly the PCV hose.

Troubleshooting vacuum leaks requires a close visual inspection of the hose, making sure it's properly connected, and listening for the telltale hissing sound of the vacuum leak.

But noise from a running engine can make it impossible to hear a hissing sound coming from a leaky vacuum hose or gasket. For this you have two options: You can use a mechanic's stethoscope that helps to amplify the sounds in your ear, or you can use a length of hose for the same purpose.

How to Check Each Vacuum Hose

Follow the next steps to check each vacuum hose, keeping a reasonable distance from moving components during your inspection:

- Start the engine and let it idle. Set the transmission to Park (automatic) or Neutral (manual) and apply the emergency brake.

- Make sure the hose is properly connected, not loose or hanging free. It's easy to knock a hose loose inadvertently when doing maintenance or replacing a component. You may need to use a small mirror and a flashlight to check on hard-to-reach places, like behind the intake manifold, throttle body, or exhaust manifold.

- Unplug and inspect both ends of the hose. If the inside end of the hose is torn, worn, or widened, cut off the damaged part and plug the hose back to the fitting.

- Trace the length of the hose with your fingers to feel for rough, hardened, splitting, softened, or out-of-shape spots, especially around the hidden, underside of the hose. Also, try to feel for vacuum at those rough or uneven spots.

- Check if the hose is near or touching a hot surface.

- Also, check hose connectors, tees, and unions for cracks and looseness. Replace them as necessary.

- Pay special attention to the check valve that connects the brake booster to its vacuum hose. If leaking, you may hear a hissing sound.

- You can check a leaking brake booster at idle by blocking the vacuum hose with a pair of Vise-Grip pliers. Use a shop rag between the pliers and hose to prevent damage. If the rough idle improves, check the brake booster and valve.

- Check the hose for contamination as well, like oil, coolant, or some other substance. Disconnect the hose from the device it connects to and check inside the device connector. If you find a foreign substance inside the hose, contamination has potentially reached inside the device as well, probably not functioning properly. You may need to test the device for proper operation.

- As part of your visual inspection, include the devices the vacuum hoses connect to. Check the devices for damage like cracks, dents, and loose parts. These may create a vacuum leak as well. Pinch the vacuum line leading to the device, and spray soapy water on it and hear for a change in idle speed.

- If you find a hose with a softened, hardened, or damaged spot, replace it.

You can also spray water on a hose, ports and connectors to help you check for leaks.

Using a Vacuum Gauge

You can also use a vacuum gauge to further confirm the presence of a vacuum leak, if necessary. If you don't own a gauge or don't want to buy one right now, your local auto parts store may loan you one.

Follow the instructions that come with the tool and the tips included in the post linked above.

Pay special attention to needle movement patterns. A steady low or very low reading may point to a gasket (intake or throttle) leak, among other potential faults.

Replace the intake manifold gasket if it develops a vacuum leak.

Photo courtesy of scottt on Flickr.

III. Checking the Intake Manifold for Vacuum Leaks

Although you're more likely to encounter a vacuum hose leak, intake manifold gasket leaks also happen. If your previous check didn't turn out anything wrong, check the intake gasket between the manifold and cylinder head, and the base gasket located between the intake manifold and throttle body or carburetor.

To check these gaskets you can use one of two simple alternative methods:

- Soapy water in a spray bottle.

- A length of hose (or mechanic's stethoscope).

Any one of these methods is good.

- Apply the emergency brakes.

- Set your transmission to Park (automatic) or Neutral (manual).

- Block the wheels to be safer and prevent the vehicle from moving.

- Start the engine and let it idle.

- To use the soapy water, spray a little around the intake manifold where it mates with the cylinder head and around the base of the carburetor or throttle body. Don't forget to visually check the intake manifold itself for cracks and spray water on suspect spots.

- Listen for any changes in the engine idle.

- If the engine smooths out as you spray water, you've found the vacuum leak; you may also see bubbles at the location of the vacuum leak.

Note: To use a hose (or mechanic's stethoscope), place one end of the hose against your ear and move the other end of the hose around the edge of the intake manifold gasket and carburetor or throttle body gasket. If there's a leak, you'll hear a hissing sound.

If you found a vacuum leak either at the intake manifold or at the base of the throttle body, first try tightening the intake or throttle body mounting bolt:

- Tighten the bolts gradually, following a crisscross pattern—when tightening a manifold, start at the center and work your way out.

- Tighten the bolts to the torque listed in your vehicle repair manual using a torque wrench.

- Check again for the vacuum leak.

- If the leak is still present, you'll need to replace the intake manifold gasket or throttle body gasket.

- Follow the instructions in your vehicle repair manual to replace either gasket.

Watch the video below to see how to use water to diagnose a misfire on cylinder one.

IV. Using a Hand Vacuum Pump to Test Devices for Vacuum Leaks

Often, a careful visual and manual inspection like the one described above is enough to find a vacuum leak. But not all the time.

Some components that operate with vacuum may suffer internal damage (a diaphragm may rupture, for example). And you can't diagnose this type of damage by touch or sight.

So, if you suspect a vacuum leak but can find the source, this is the next step in your troubleshooting strategy.

For this, you'll need to use a hand-operated vacuum pump. You may buy one at most auto parts stores or online. The vacuum pump helps in troubleshooting emission systems. But if you don't want to buy the tool right now, your local auto parts store may loan you one.

Follow the instructions that come with the vacuum pump for operation instructions and the repair manual for your particular vehicle for the steps in troubleshooting the device you need to test.

Sometimes you need to troubleshoot a device under specific operating conditions, or in conjunction with another tool. Although this type of troubleshooting may sound complicated, you don't need special training. You do still need to follow the tool operating instructions, however, and the repair manual troubleshooting steps.

Also, follow these tips when using a vacuum pump:

- Make sure the connection between the pump and the device is tight—use the correct diameter connector or hose to make the connection.

- Only apply the right amount of vacuum for the device you are testing (usually 10 to 15 in Hg; consult your repair manual).

- The fewer connectors, adapters, and hoses you use to connect your hand pump to the device you want to test, the better.

You can use a union to repair small vacuum hose leaks.

Photo courtesy of James A O on Flickr.

V. Vacuum Hose Repair Tips

Dealing with damaged vacuum hoses doesn't necessarily mean you need to replace them. Often, a vacuum hose only requires a simple repair that can take you a couple of minutes or so.

- You can repair a damaged vacuum hose end in a minute. Most of the time you can get away with cutting off about half an inch at the end and reconnecting the hose.

- Be careful when dealing with damage located between the ends of a vacuum hose. If you just need to repair a small hole of less than half an inch, cut out the damaged area and use a union to reconnect the two pieces back.

- Repair one vacuum hose at a time to avoid confusion. Some vehicles, especially Asian brands, come with several vacuum hoses that can make it confusing to repair when they interconnect in various ways. For these cases, you can find 1-, 2-, 3-, 4-way, and elbow connectors to deal with almost any kind of hose routing and repair.

- Always label hoses and their respective connectors or fittings, so that you reinstall repaired or new hoses to their corresponding fittings.

- If you find one or more disconnected hoses, use your vacuum diagram to reconnect the hose to the correct fitting.

- After making a repair, route and secure the vacuum hose away from hot surfaces and moving components.

- Always replace a vacuum hose with one of the same diameter and length, and for the application intended (PCV, brake booster, or regular vacuum).

This content is accurate and true to the best of the author's knowledge and is not meant to substitute for formal and individualized advice from a qualified professional.

Questions & Answers

Question: My check engine light came on, and I went to the mechanic who said it was a P0171 error. Bank 1 system 2 lead too lean. I cleaned the mass air flow sensor and all was fine for around 800 miles and two weeks. However, it returned with the same code. I pulled out the MAF sensor to see if it was dirty and it looked fine. What is my next step?

Answer: This other post may help:

https://axleaddict.com/auto-repair/Trouble-Code-P0...

Question: When fixing a vacuum leak, how long after resetting the p071 code will it revert if not fixed?

Answer: In general, if you are dealing with an intermittent problem, it may take a while for the light to come back on, until the part fails again and the computer detects the problem. If there's a failed, monitored part, it probably will take a few hours for the computer to detect it again.

Question: What are the most common vacuum leaks on the manifold?

Answer: Check vacuum hoses condition and connectors. Then check for intake gasket leaks. Sometimes spraying some carburetor cleaner on suspected leaks helps to find damaged hoses and leaks.

Question: If I disconnect a vacuum hose and hear a hissing sound, does that indicate that my vacuum is good? Meaning, if there is a leak, there wouldn't be a proper seal to keep that pressure/vacuum on the line and no hiss would emit when the line is disconnected.

Answer: It is hard to find a small leak just by disconnecting a vacuum hose. You'd think the hose and fitting are perfectly good. A vacuum may leak through damaged hoses, gaskets, and faulty valves. If you are suspecting a leak, try using a vacuum gauge. It'll be more accurate. This other post may help:

https://axleaddict.com/auto-repair/Use-a-Vacuum-Ga...

Question: I'm restoring a 50-year old Jeepster 258-6. I have replaced the intake manifold gasket and put on headers. My jeep starts up but within 3 seconds, the RPM sounds like it shoots up to about 2500 and dies. Could it be the gasket? The jeep will only run for 3 seconds.

Answer: It seems like a huge vacuum leak. It could be the intake manifold or base carburetor gasket. Your local auto parts store may loan you a smoke machine. Hook it up to the brake booster hose. Hope this helps.

Question: What could my problem be? My 2001 Chevy Blazer has constant air sound. Noise is inside the cabin and rises at idle only while break is pressed. No fluid loss but with the ignition off, I pump the brakes, they don't get harder, and yet they sink if held while starting, feel spongy and pedal almost sink to the floor. Just beginning to learn about diagnosing for a vacuum leak. I will check the hoses tomorrow. And your help would be greatly appreciated. Any ideas?

Answer: It sounds like you may have a vacuum leak in the brake booster. This other post may help you diagnose the problem:

https://axleaddict.com/auto-repair/Bad-Brake-Boost...

Question: How do you fix an air leak on a box stock go-kart motor?

Answer: Check the gaskets; the one between the carburetor and air box might be leaking.

© 2016 Dan Ferrell

Source: https://axleaddict.com/auto-repair/How-to-Find-and-Fix-a-Vacuum-Leak

0 Response to "Easy Way to Find Vacuum Leak in My Ford Van"

Post a Comment